Exhibit 99.2 Introduction Investor Presentation August 2021Exhibit 99.2 Introduction Investor Presentation August 2021

2 Disclaimer Forward-Looking Statements. Certain statements in this presentation (the “Presentation”) may be considered forward-looking statements. Forward-looking statements generally relate to future events or the Company’s future financial or operating performance. For example, statements concerning the following include forward-looking statements: development plans for Markforged’s products; Markforged’s sales projections and financial estimates; the size and growth of the additive manufacturing market; the adoption of Markforged’s products in the manufacturing industry and other industries; and the potential effects of the Business Combination on the Company. In some cases, you can identify forward-looking statements by terminology such as “may”, “should”, “expect”, “intend”, “will”, “estimate”, “anticipate”, “believe”, “predict”, “potential” or “continue”, or the negatives of these terms or variations of them or similar terminology. Such forward-looking statements are subject to risks, uncertainties, and other factors which could cause actual results to differ materially from those expressed or implied by such forward looking statements. These forward-looking statements are based upon estimates and assumptions that, while considered reasonable by Markforged and its management, are inherently uncertain. New risks and uncertainties may emerge from time to time, and it is not possible to predict all risks and uncertainties. Factors that may cause actual results to differ materially from current expectations include, but are not limited to, various factors beyond management’s control including the effects of the COVID-19 pandemic, general economic conditions and other risks, uncertainties and factors set forth in the section entitled “Risk Factors” and “Cautionary Note Regarding Forward-Looking Statements” in the Company’s most recent registration statement on Form S-1, the Company’s periodic report on Form 10-Q for the quarter ended June 30, 2021 and other filings with the Securities and Exchange Commission (‘SEC”), as well as factors associated with companies, such as the Company, that are engaged in additive manufacturing. Nothing in this Presentation should be regarded as a representation by any person that the forward-looking statements set forth herein will be achieved or that any of the contemplated results of such forward-looking statements will be achieved. You should not place undue reliance on forward-looking statements in this Presentation, which speak only as of the date they are made and are qualified in their entirety by reference to the cautionary statements herein. The Company undertakes no obligation to update these forward-looking statements. Market and Industry Data. Certain information contained in this Presentation relates to or is based on publications, surveys and the Company’s own internal estimates and research. In addition, all of the market data included in this Presentation involves a number of assumptions and limitations, and there can be no guarantee as to the accuracy or reliability of such assumptions. Finally, while the Company believes its internal research is reliable, such research has not been verified by any independent source. Use of Non-GAAP Financial Metrics. This Presentation may include certain non-GAAP financial measures (including on a forward-looking basis) such as Adjusted EBITDA and Free Cash Flow. These non-GAAP measures are an addition to, and not a substitute for or superior to, measures of financial performance prepared in accordance with GAAP and should not be considered as an alternative to net income, operating income or any other performance measures derived in accordance with GAAP. Reconciliations of non-GAAP measures to their most directly comparable GAAP counterparts are included in the Appendix to this presentation. Markforged believes that these non-GAAP measures of financial results (including on a forward-looking basis) provide useful supplemental information to investors about Markforged. Markforged’s management uses forward- looking non-GAAP measures to evaluate Markforged’s projected financials and operating performance. However, there are a number of limitations related to the use of these non-GAAP measures and their nearest GAAP equivalents, including that they exclude significant expenses that are required by GAAP to be recorded in Markforged’s financial measures. In addition, other companies may calculate non-GAAP measures differently, or may use other measures to calculate their financial performance, and therefore, Markforged’s non-GAAP measures may not be directly comparable to similarly titled measures of other companies. Additionally, to the extent that forward-looking non-GAAP financial measures are provided, they are presented on a non-GAAP basis without reconciliations of such forward-looking non-GAAP measures due to the inherent difficulty in forecasting and quantifying certain amounts that are necessary for such reconciliations.2 Disclaimer Forward-Looking Statements. Certain statements in this presentation (the “Presentation”) may be considered forward-looking statements. Forward-looking statements generally relate to future events or the Company’s future financial or operating performance. For example, statements concerning the following include forward-looking statements: development plans for Markforged’s products; Markforged’s sales projections and financial estimates; the size and growth of the additive manufacturing market; the adoption of Markforged’s products in the manufacturing industry and other industries; and the potential effects of the Business Combination on the Company. In some cases, you can identify forward-looking statements by terminology such as “may”, “should”, “expect”, “intend”, “will”, “estimate”, “anticipate”, “believe”, “predict”, “potential” or “continue”, or the negatives of these terms or variations of them or similar terminology. Such forward-looking statements are subject to risks, uncertainties, and other factors which could cause actual results to differ materially from those expressed or implied by such forward looking statements. These forward-looking statements are based upon estimates and assumptions that, while considered reasonable by Markforged and its management, are inherently uncertain. New risks and uncertainties may emerge from time to time, and it is not possible to predict all risks and uncertainties. Factors that may cause actual results to differ materially from current expectations include, but are not limited to, various factors beyond management’s control including the effects of the COVID-19 pandemic, general economic conditions and other risks, uncertainties and factors set forth in the section entitled “Risk Factors” and “Cautionary Note Regarding Forward-Looking Statements” in the Company’s most recent registration statement on Form S-1, the Company’s periodic report on Form 10-Q for the quarter ended June 30, 2021 and other filings with the Securities and Exchange Commission (‘SEC”), as well as factors associated with companies, such as the Company, that are engaged in additive manufacturing. Nothing in this Presentation should be regarded as a representation by any person that the forward-looking statements set forth herein will be achieved or that any of the contemplated results of such forward-looking statements will be achieved. You should not place undue reliance on forward-looking statements in this Presentation, which speak only as of the date they are made and are qualified in their entirety by reference to the cautionary statements herein. The Company undertakes no obligation to update these forward-looking statements. Market and Industry Data. Certain information contained in this Presentation relates to or is based on publications, surveys and the Company’s own internal estimates and research. In addition, all of the market data included in this Presentation involves a number of assumptions and limitations, and there can be no guarantee as to the accuracy or reliability of such assumptions. Finally, while the Company believes its internal research is reliable, such research has not been verified by any independent source. Use of Non-GAAP Financial Metrics. This Presentation may include certain non-GAAP financial measures (including on a forward-looking basis) such as Adjusted EBITDA and Free Cash Flow. These non-GAAP measures are an addition to, and not a substitute for or superior to, measures of financial performance prepared in accordance with GAAP and should not be considered as an alternative to net income, operating income or any other performance measures derived in accordance with GAAP. Reconciliations of non-GAAP measures to their most directly comparable GAAP counterparts are included in the Appendix to this presentation. Markforged believes that these non-GAAP measures of financial results (including on a forward-looking basis) provide useful supplemental information to investors about Markforged. Markforged’s management uses forward- looking non-GAAP measures to evaluate Markforged’s projected financials and operating performance. However, there are a number of limitations related to the use of these non-GAAP measures and their nearest GAAP equivalents, including that they exclude significant expenses that are required by GAAP to be recorded in Markforged’s financial measures. In addition, other companies may calculate non-GAAP measures differently, or may use other measures to calculate their financial performance, and therefore, Markforged’s non-GAAP measures may not be directly comparable to similarly titled measures of other companies. Additionally, to the extent that forward-looking non-GAAP financial measures are provided, they are presented on a non-GAAP basis without reconciliations of such forward-looking non-GAAP measures due to the inherent difficulty in forecasting and quantifying certain amounts that are necessary for such reconciliations.

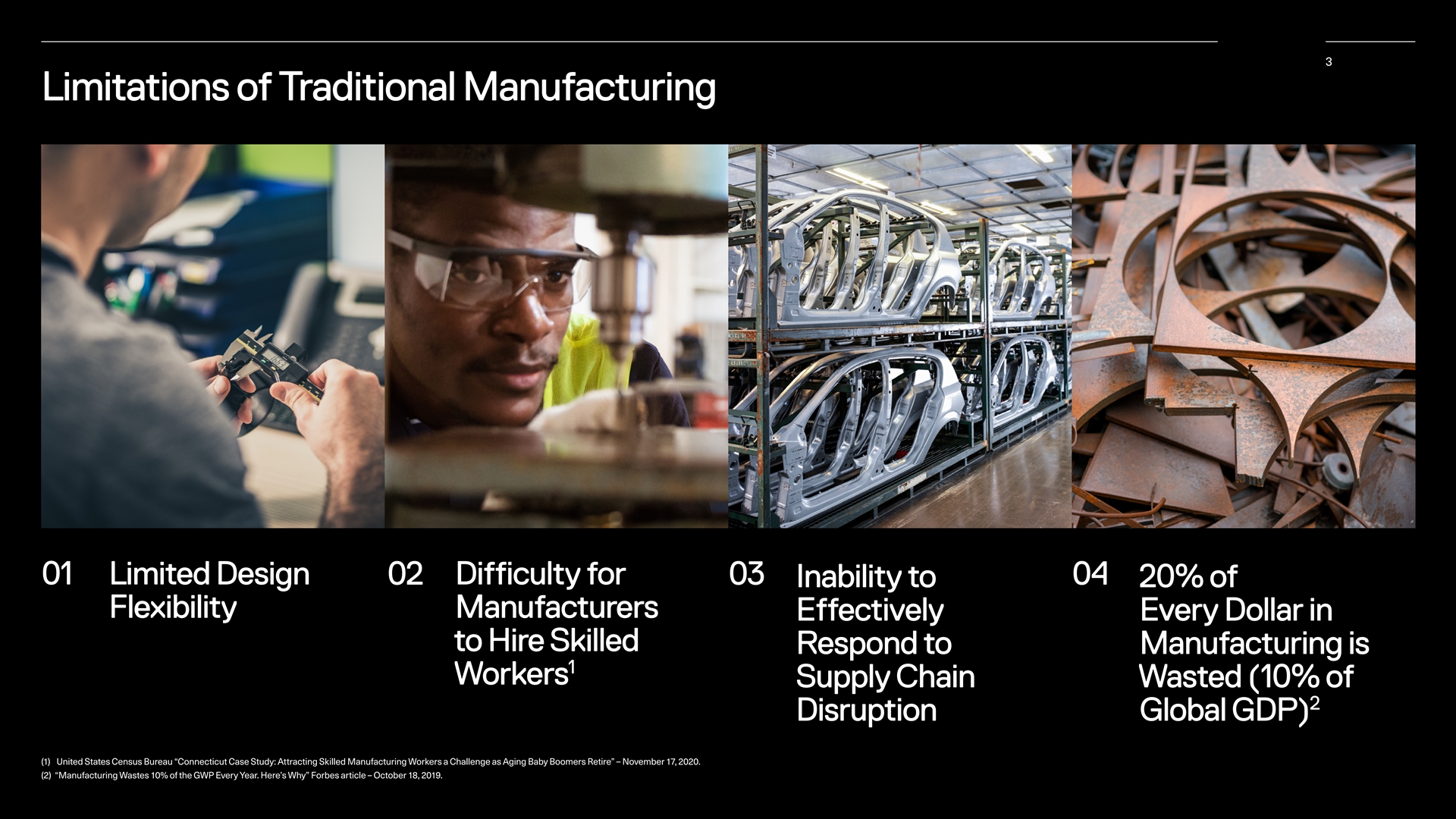

3 Limitations of Traditional Manufacturing 01 Limited Design 02 Difficulty for 03 04 Inability to 20% of Flexibility Manufacturers Effectively Every Dollar in to Hire Skilled Respond to Manufacturing is 1 Workers Supply Chain Wasted (10% of 2 Disruption Global GDP) (1) United States Census Bureau “Connecticut Case Study: Attracting Skilled Manufacturing Workers a Challenge as Aging Baby Boomers Retire” – November 17, 2020. (2) “Manufacturing Wastes 10% of the GWP Every Year. Here’s Why” Forbes article – October 18, 2019.3 Limitations of Traditional Manufacturing 01 Limited Design 02 Difficulty for 03 04 Inability to 20% of Flexibility Manufacturers Effectively Every Dollar in to Hire Skilled Respond to Manufacturing is 1 Workers Supply Chain Wasted (10% of 2 Disruption Global GDP) (1) United States Census Bureau “Connecticut Case Study: Attracting Skilled Manufacturing Workers a Challenge as Aging Baby Boomers Retire” – November 17, 2020. (2) “Manufacturing Wastes 10% of the GWP Every Year. Here’s Why” Forbes article – October 18, 2019.

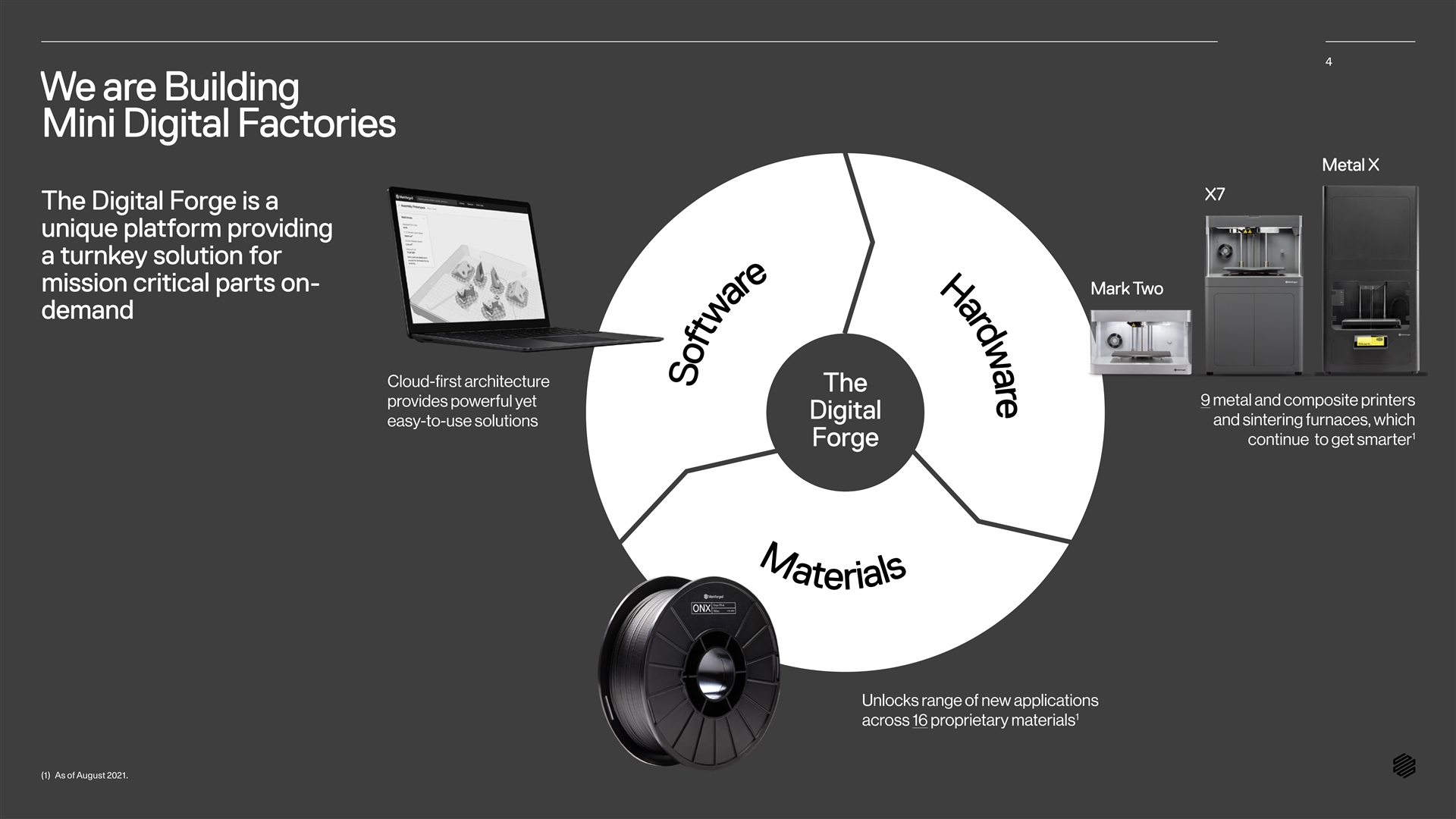

4 We are Building Mini Digital Factories Metal X X7 The Digital Forge is a unique platform providing a turnkey solution for mission critical parts on- Mark Two demand Cloud-first architecture The 9 metal and composite printers provides powerful yet Digital and sintering furnaces, which easy-to-use solutions 1 continue to get smarter Forge Unlocks range of new applications 1 across 16 proprietary materials (1) As of August 2021.4 We are Building Mini Digital Factories Metal X X7 The Digital Forge is a unique platform providing a turnkey solution for mission critical parts on- Mark Two demand Cloud-first architecture The 9 metal and composite printers provides powerful yet Digital and sintering furnaces, which easy-to-use solutions 1 continue to get smarter Forge Unlocks range of new applications 1 across 16 proprietary materials (1) As of August 2021.

5 Accessible, Industrial-Grade Solution. Today Upgrading metal High and Integrated, Scale today with advanced tangible modern software drives virtuous composites customer ROI platform cycle Wide range of Mission-critical Continuous software More customers > proprietary composite application for blue- updates drive faster More part data > Printers and metal materials chip customers with evidenced innovation and get smarter > Better parts address broad range land-and-expand deployment of applications

The Next ChapterThe Next Chapter

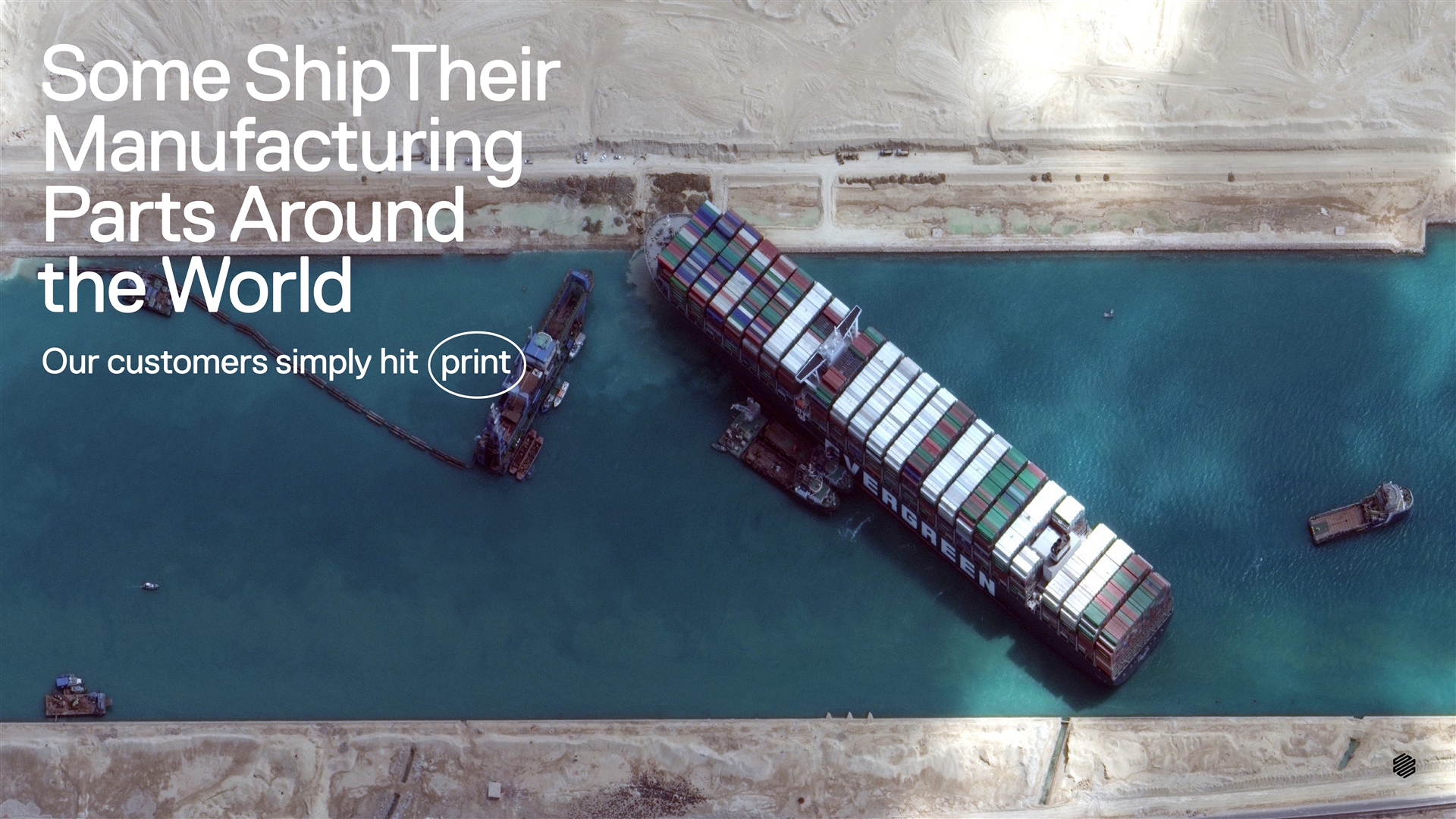

Some ShipTheir Manufacturing Parts Around the World Our customers simply hit printSome ShipTheir Manufacturing Parts Around the World Our customers simply hit print

Markforged Leads the Future of Distributed Manufacturing Cloud architecture enables customers to print mission critical parts on-demand at the point of needMarkforged Leads the Future of Distributed Manufacturing Cloud architecture enables customers to print mission critical parts on-demand at the point of need

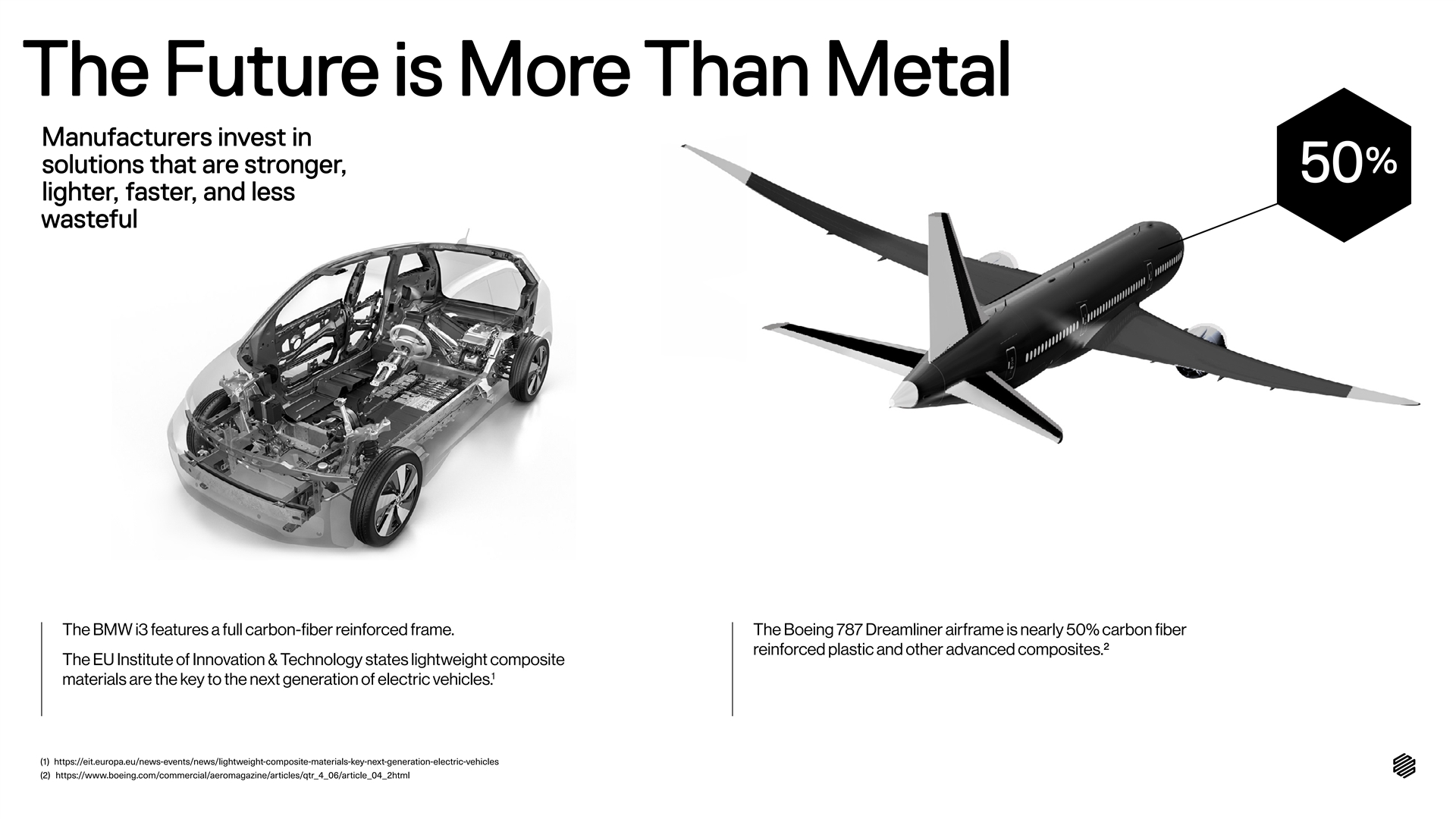

The Future is More Than Metal Manufacturers invest in solutions that are stronger, % 50 lighter, faster, and less wasteful The BMW i3 features a full carbon-fiber reinforced frame. The Boeing 787 Dreamliner airframe is nearly 50% carbon fiber reinforced plastic and other advanced composites.2 The EU Institute of Innovation & Technology states lightweight composite 1 materials are the key to the next generation of electric vehicles. (1) https://eit.europa.eu/news-events/news/lightweight-composite-materials-key-next-generation-electric-vehicles (2) https://www.boeing.com/commercial/aeromagazine/articles/qtr_4_06/article_04_2htmlThe Future is More Than Metal Manufacturers invest in solutions that are stronger, % 50 lighter, faster, and less wasteful The BMW i3 features a full carbon-fiber reinforced frame. The Boeing 787 Dreamliner airframe is nearly 50% carbon fiber reinforced plastic and other advanced composites.2 The EU Institute of Innovation & Technology states lightweight composite 1 materials are the key to the next generation of electric vehicles. (1) https://eit.europa.eu/news-events/news/lightweight-composite-materials-key-next-generation-electric-vehicles (2) https://www.boeing.com/commercial/aeromagazine/articles/qtr_4_06/article_04_2html

Markforged 2.0 – From Accessible End-Use Parts to Robust ProductionMarkforged 2.0 – From Accessible End-Use Parts to Robust Production

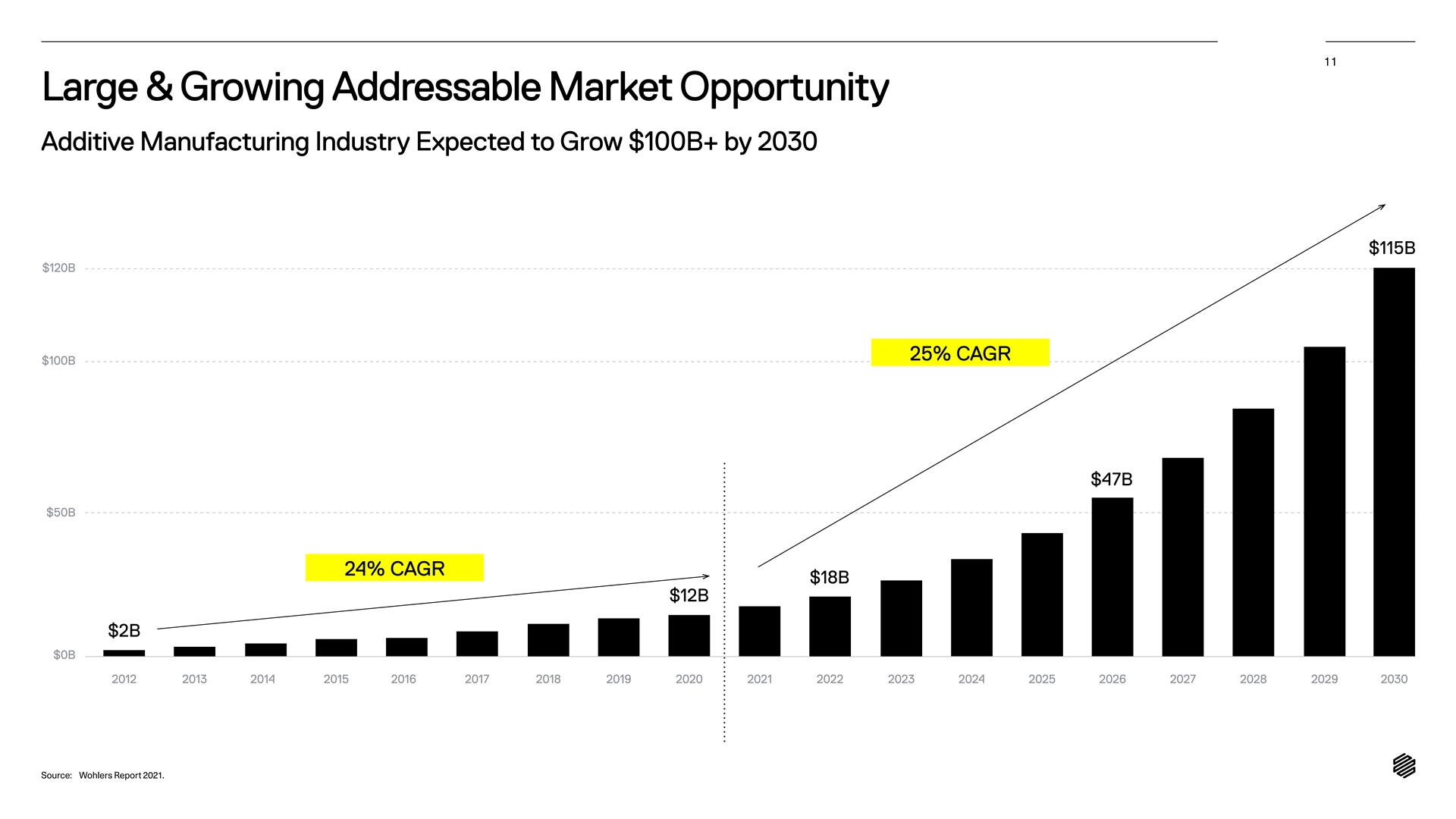

11 Large & Growing Addressable Market Opportunity Additive Manufacturing Industry Expected to Grow $100B+ by 2030 $115B $120B 25% CAGR $100B $47B $50B 24% CAGR $18B $12B $2B $0B 2012 2013 2014 2015 2016 2017 2018 2019 2020 2021 2022 2023 2024 2025 2026 2027 2028 2029 2030 Source: Wohlers Report 2021.11 Large & Growing Addressable Market Opportunity Additive Manufacturing Industry Expected to Grow $100B+ by 2030 $115B $120B 25% CAGR $100B $47B $50B 24% CAGR $18B $12B $2B $0B 2012 2013 2014 2015 2016 2017 2018 2019 2020 2021 2022 2023 2024 2025 2026 2027 2028 2029 2030 Source: Wohlers Report 2021.

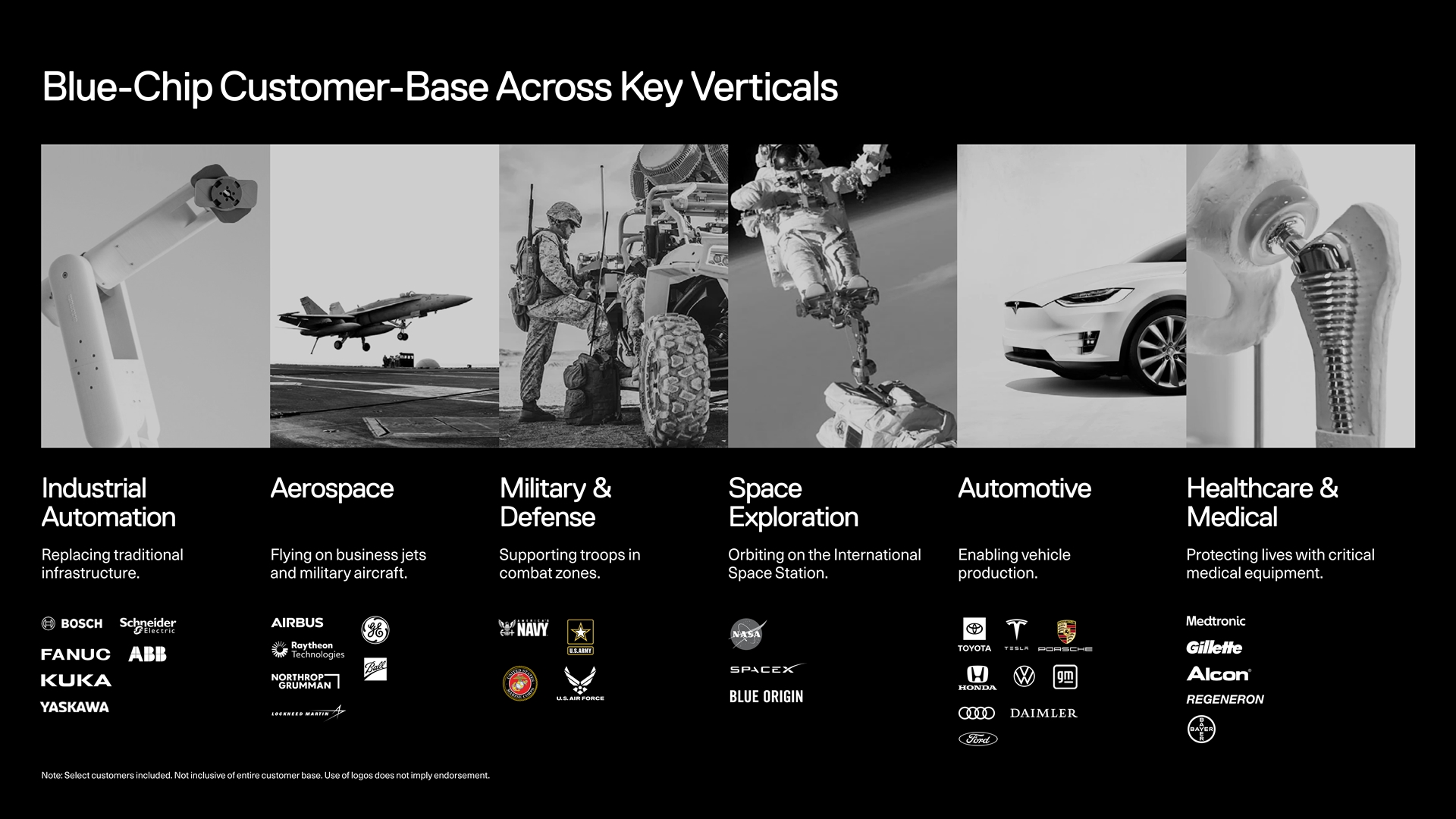

Blue-Chip Customer-Base Across Key Verticals Industrial Aerospace Military & Space Automotive Healthcare & Automation Defense Exploration Medical Replacing traditional Flying on business jets Supporting troops in Orbiting on the International Enabling vehicle Protecting lives with critical infrastructure. and military aircraft. combat zones. Space Station. production. medical equipment. Note: Select customers included. Not inclusive of entire customer base. Use of logos does not imply endorsement.Blue-Chip Customer-Base Across Key Verticals Industrial Aerospace Military & Space Automotive Healthcare & Automation Defense Exploration Medical Replacing traditional Flying on business jets Supporting troops in Orbiting on the International Enabling vehicle Protecting lives with critical infrastructure. and military aircraft. combat zones. Space Station. production. medical equipment. Note: Select customers included. Not inclusive of entire customer base. Use of logos does not imply endorsement.

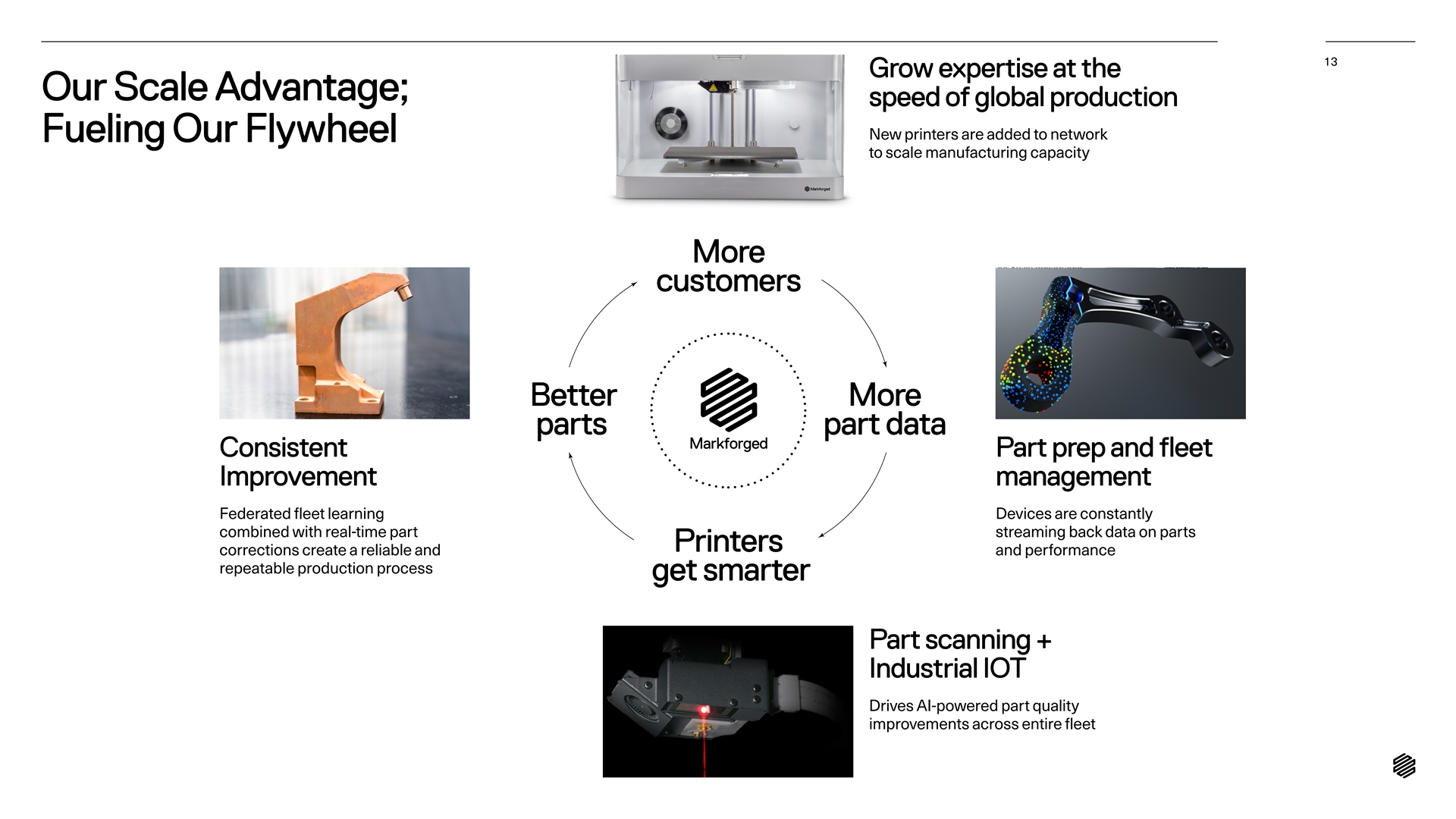

13 Grow expertise at the Our Scale Advantage; speed of global production New printers are added to network Fueling Our Flywheel to scale manufacturing capacity More customers Better More parts part data Consistent Part prep and fleet Improvement management Federated fleet learning Devices are constantly combined with real-time part streaming back data on parts Printers corrections create a reliable and and performance repeatable production process get smarter Part scanning + Industrial IOT Drives AI-powered part quality improvements across entire fleet13 Grow expertise at the Our Scale Advantage; speed of global production New printers are added to network Fueling Our Flywheel to scale manufacturing capacity More customers Better More parts part data Consistent Part prep and fleet Improvement management Federated fleet learning Devices are constantly combined with real-time part streaming back data on parts Printers corrections create a reliable and and performance repeatable production process get smarter Part scanning + Industrial IOT Drives AI-powered part quality improvements across entire fleet

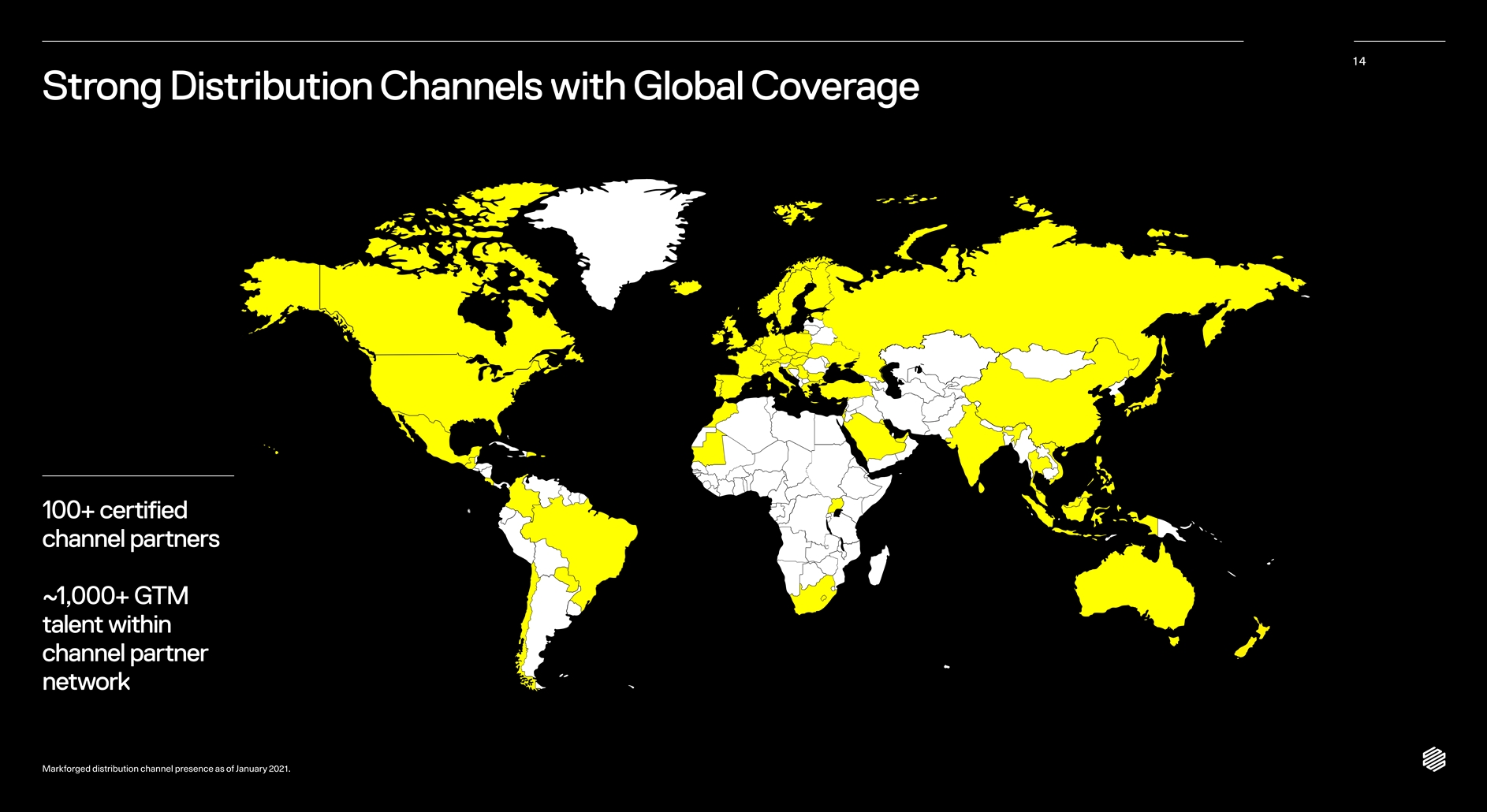

14 Strong Distribution Channels with Global Coverage 100+ certified channel partners ~1,000+ GTM talent within channel partner network Markforged distribution channel presence as of January 2021.14 Strong Distribution Channels with Global Coverage 100+ certified channel partners ~1,000+ GTM talent within channel partner network Markforged distribution channel presence as of January 2021.

15 Experienced & Visionary Management Team to Drive Us Forward Leadership Shai Terem Mark Schwartz Dorit Liberman Ken Clayton David Benhaim President & CEO Chief Financial Officer Chief Human SVP, Global Sales Co-Founder & CTO Resources Officer John Howard Stephen Karp Assaf Zipori Matt Gannon Daniel Eiref VP, Engineering General Counsel VP, Corporate Development VP, Operations Senior Director Product and Strategy Management Michael Papish Ved Nararyan Brian Houle VP, Marketing VP Sales, APAC VP Sales, EMEA15 Experienced & Visionary Management Team to Drive Us Forward Leadership Shai Terem Mark Schwartz Dorit Liberman Ken Clayton David Benhaim President & CEO Chief Financial Officer Chief Human SVP, Global Sales Co-Founder & CTO Resources Officer John Howard Stephen Karp Assaf Zipori Matt Gannon Daniel Eiref VP, Engineering General Counsel VP, Corporate Development VP, Operations Senior Director Product and Strategy Management Michael Papish Ved Nararyan Brian Houle VP, Marketing VP Sales, APAC VP Sales, EMEA

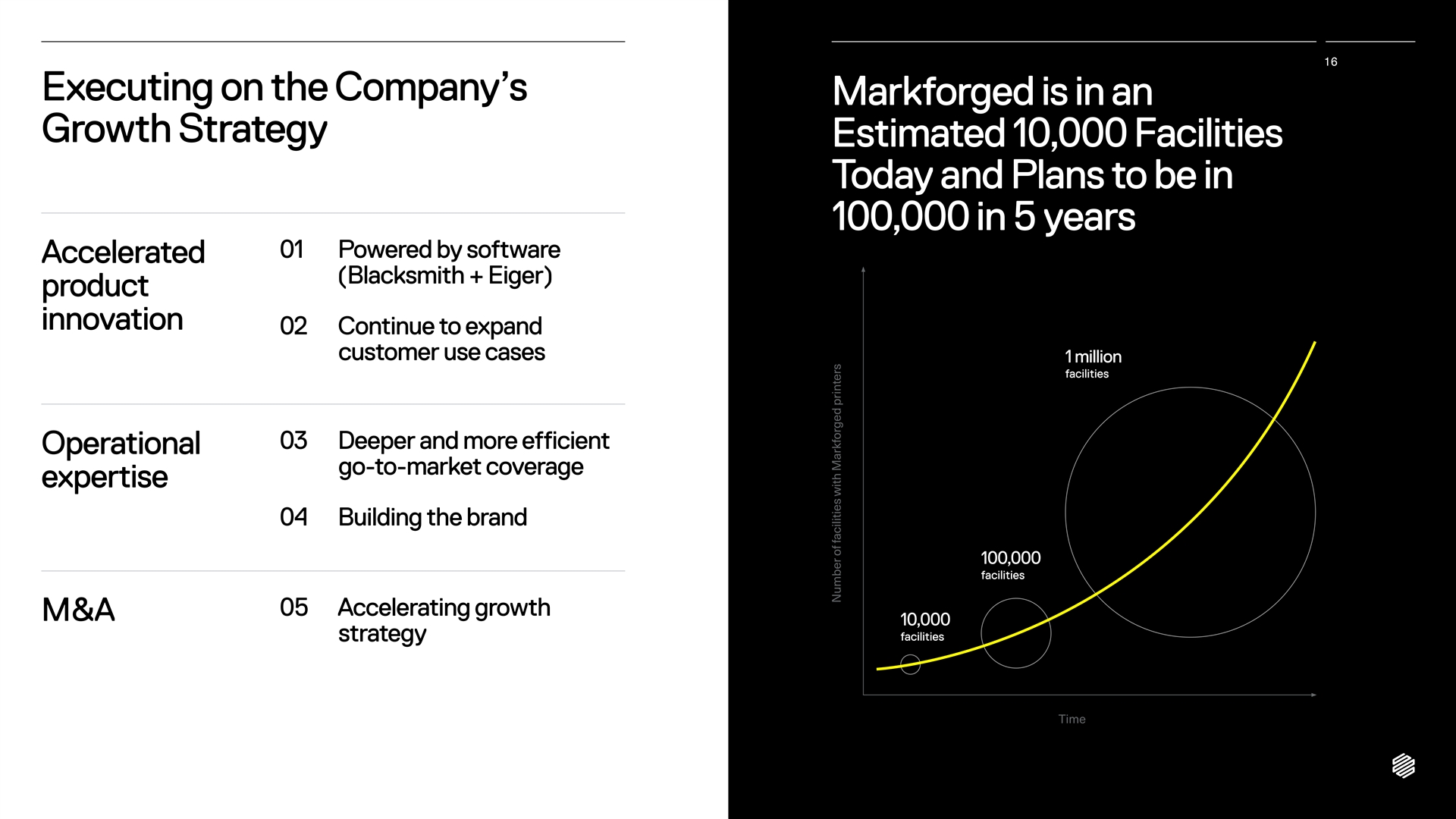

16 Executing on the Company’s Markforged is in an Growth Strategy Estimated 10,000 Facilities Today and Plans to be in 100,000 in 5 years 01 Powered by software Accelerated (Blacksmith + Eiger) product innovation 02 Continue to expand customer use cases 1 million facilities 03 Deeper and more efficient Operational go-to-market coverage expertise 04 Building the brand 100,000 facilities 05 Accelerating growth M&A 10,000 facilities strategy Time Number of facilities with Markforged printers16 Executing on the Company’s Markforged is in an Growth Strategy Estimated 10,000 Facilities Today and Plans to be in 100,000 in 5 years 01 Powered by software Accelerated (Blacksmith + Eiger) product innovation 02 Continue to expand customer use cases 1 million facilities 03 Deeper and more efficient Operational go-to-market coverage expertise 04 Building the brand 100,000 facilities 05 Accelerating growth M&A 10,000 facilities strategy Time Number of facilities with Markforged printers

IntroductionIntroduction