Markforged Introduces Two New Industrial 3D Printers For Local Manufacturing

New X3 and X5 models make it possible to replace aluminum parts with carbon fiber parts that are up to 20X stronger and cost 20X less

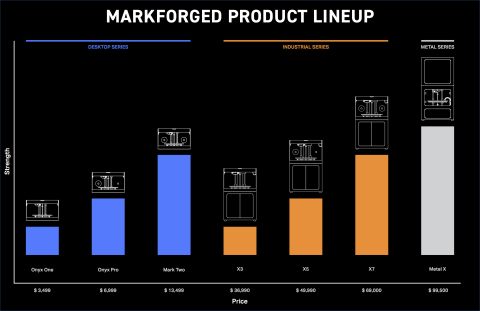

CAMBRIDGE, Mass.--(BUSINESS WIRE)-- Markforged, the only 3D printing platform that prints the entire range of strong parts from carbon fiber to metal with a complete cloud managed 3D solution, today announced the addition of two new printers to the company’s Industrial Series. Markforged’s new X3 and X5 printers introduce price points that enable customers to print stronger, larger, and lighter parts.

This Smart News Release features multimedia. View the full release here: http://www.businesswire.com/news/home/20170816005273/en/

“For 30 years, 3D printing customers have been forced to accept trade-offs between strength, time, and affordability -- lacking the opportunity to benefit from all three. With the complete Industrial Series and new Metal X printer, these trade-offs no longer exist,” said Greg Mark, Markforged’s founder and CEO. “Customers can now, with ease, print same-day parts that optimize strength and affordability for their specific needs.” (Graphic: Business Wire)

Local manufacturers are often at a disadvantage because they are forced to choose between the sub-par strength of printed parts and long lead times associated with machined parts. With the arrival of the X3 and X5 printers, Markforged has made industrial strength printing financially attainable for every manufacturing business, allowing them to better compete on a global stage.

The X3 is powered by the incredible material strength and stiffness of Onyx, a high temperature capable carbon fiber filled nylon. The X3 prints strictly engineering grade thermoplastic fiber parts, and is available at the disruptive price point of $36,990.

The X5 adds the ability to reinforce an Onyx part with a strand of continuous fiberglass, making it 19X stronger and 10X stiffer than traditional plastics. The X5, workhorse of the industrial line, has the unique ability to deliver parts that are both strong and affordable for only $49,900.

The X7, previously known as the Mark X, remains Markforged’s flagship Continuous Carbon Fiber (CCF) industrial printer platform, yielding 23X stronger parts than with ABS materials. The X7 boasts the industry’s only sub-$1M in-part laser inspection for reliable quality control with a price point of $69,000.

Customers can future-proof their investments as Markforged offers an affordable, industry-exclusive upgrade program allowing customers at any time to leverage their initial investment in an X3 to upgrade to an X5 or X7, gaining access to higher strength materials and inspection utilities.

Long time Markforged customer Dixon Valve, a 100-year-old hose fittings and accessories company, has accelerated their manufacturing in part powered by the use of Markforged printers. The company was able to bring their high strength printing needs in-house, saving both time and money and arriving at a more efficient process that has helped to drive their position as a consistent industry leader.

“Our first Markforged printer paid itself off in less than 1.5 months and saved us over 81% versus machining,” said Bill Hollingsworth, vice president of engineering at Dixon Valve. “This is why we're excited to be first in line to bring the capabilities of one of Markforged's new industrial line printers in-house."

All Markforged printers share a single software ecosystem built on a next generation, cloud-based platform designed from the ground up to protect intellectual property.

“For 30 years, 3D printing customers have been forced to accept trade-offs between strength, time, and affordability -- lacking the opportunity to benefit from all three. With the complete Industrial Series and new Metal X printer, these trade-offs no longer exist,” said Greg Mark, Markforged’s founder and CEO. “Customers can now, with ease, print same-day parts that optimize strength and affordability for their specific needs.”

To learn more about the Industrial Series, visit www.markforged.com.

About Markforged

At Markforged, we are on a mission to fuel

the next 10x innovation in design and manufacturing. We build an

Industrial 3D Printing Platform to liberate designers and engineers from

decades-old, slow part creation processes.

NASA, Google, Ford, Amazon, General Electric and thousands of companies in 50 countries use Markforged to print same-day prototypes and produce stronger end-use parts than they did before. With Markforged, customers are able to ship 50% faster, spend 20% less, and build 20% stronger products.

The Markforged platform includes a full ecosystem of 3D printers for metal, composite, and plastic parts; purpose-built metal & carbon-reinforced materials for strength and beautiful finishes; and cloud software for turning drawings into high-strength printing.

For more information, and to learn why Markforged has grown over 300% in 2017, visit www.Markforged.com.

CONFIDENTIALITY NOTICE - The contents of this email message and any attachments are intended solely for the addressee(s) and contain Proprietary Information. If an agreement such as a Non Disclosure or Proprietary Information Agreement (collectively "NDA") becomes effective between the parties, you are hereby notified that the contents of this email, and/or any meeting, telephone call, presentation, or other oral or visual communication between the parties that is referred to herein, are Proprietary Information under the NDA unless otherwise specified. Employees or contractors of departments or agencies of the United States are hereby notified that this email contains information that concerns or relates to the trade secrets, processes, operations, and/or style of work of Markforged, Inc., under the Trade Secrets Act (18 U.S.C. § 1905)

View source version on businesswire.com: http://www.businesswire.com/news/home/20170816005273/en/

Markforged

Kerry Murphy, 617-412-8738

Communications

Manager

kerry@markforged.com

Source: Markforged

Released August 16, 2017